Why a Shed Wood Workshop Changes Everything for Woodworkers

A shed wood workshop is the ultimate solution for woodworkers who need dedicated space, better organization, and year-round comfort. Moving your craft out of a cramped garage or basement into a purpose-built structure gives you room to work safely, store tools efficiently, and focus on your projects without competing for space with cars, lawn equipment, or holiday decorations.

Key Benefits of a Dedicated Shed Wood Workshop:

- Separation from Living Space: Keep sawdust, noise, and fumes away from your home.

- Custom Layout: Design your workspace around your specific tools and workflow.

- Climate Control: Add insulation and heating/cooling for comfortable year-round use.

- Better Organization: Dedicated storage for lumber, hardware, and hand tools.

- Increased Property Value: A well-built workshop adds lasting appeal to your home.

At Wright’s Shed Co., we have built thousands of custom sheds across Utah, Idaho, Nebraska, and Iowa since 1997. Whether you’re converting an existing structure or starting from scratch, we’ve learned that a well-planned shed wood workshop transforms how you approach your craft. It gives you the dedicated space every woodworker deserves.

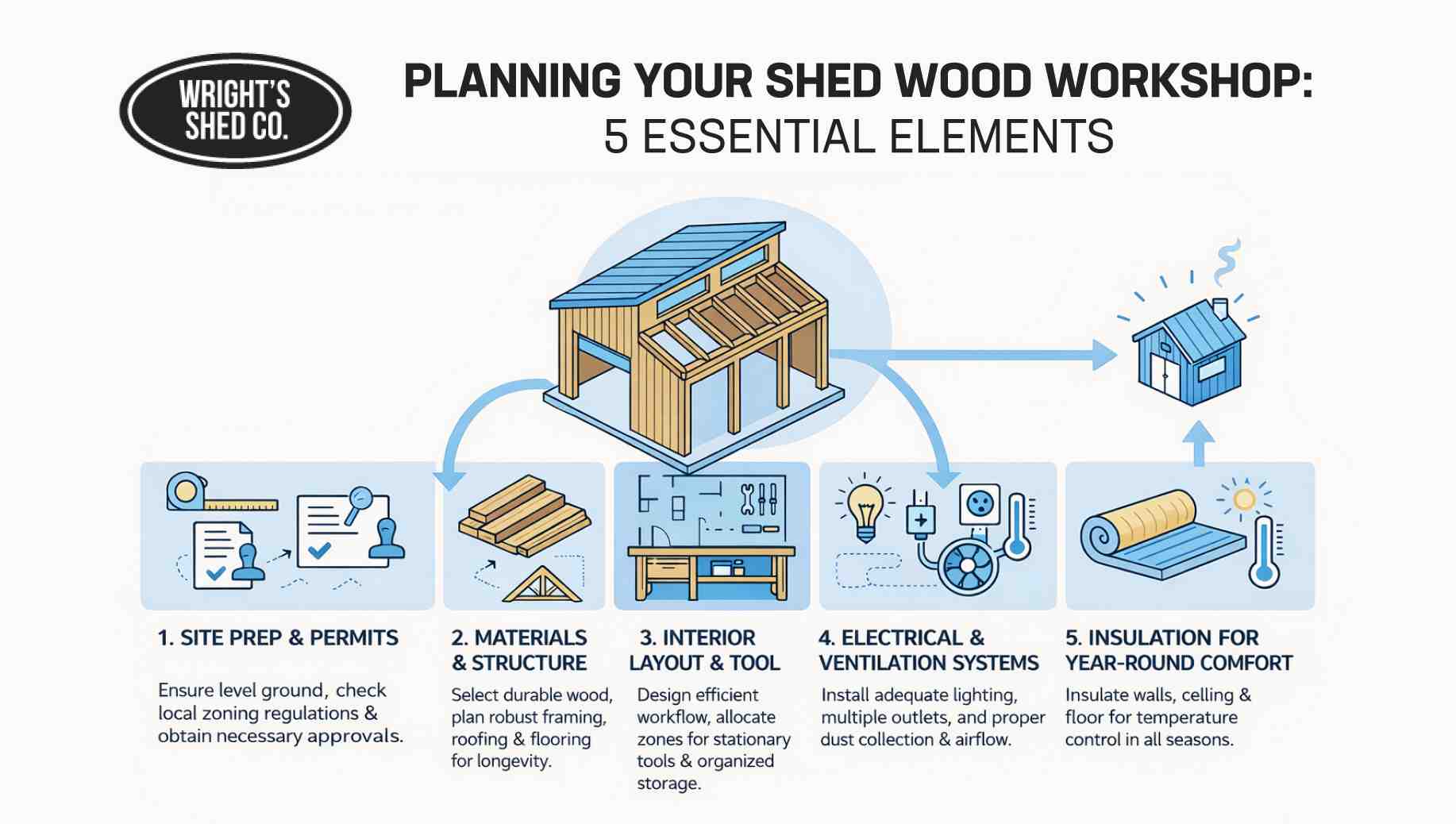

Planning Your Shed Wood Workshop: Foundation and Design

Changing your backyard into a functional woodworking haven starts with a solid plan. A well-designed shed wood workshop becomes the heart of your craft, offering a dedicated space to hone your skills. Here’s how to get started:

Step 1: Site Prep, Permits, and Foundation

Before breaking ground, it’s crucial to check with your local municipality in Utah, Idaho, Iowa, or Nebraska for building codes and permit requirements. Shed size and placement often determine what’s allowed. Ignoring these steps can lead to costly delays or fines, so always verify local regulations first.

At Wright’s Shed Co., we specialize in custom-built sheds, giving you full control over layout, window placement, and door size. This customization is a significant advantage over pre-fabricated options, allowing us to build a shed wood workshop that perfectly fits your unique needs. For the foundation, we recommend a perfectly level concrete pad or a compacted gravel base.

While we do not build foundations ourselves, we can advise on the best options for your site. A stable base ensures a long-lasting workshop. Learn more about Shed Foundation Types to choose the right one for your project.

Step 2: Choosing Materials and Structure for Longevity

The right materials ensure your shed wood workshop stands the test of time and provides a safe, durable environment for your woodworking. We use standard wood framing with 16-inch on-center studs for maximum structural integrity. This robust construction method provides a sturdy framework that can withstand the demands of a busy workshop.

For exterior siding, our sheds feature LP SmartSide panel siding, which comes with an impressive 50-year factory warranty. This material is specifically chosen for its durability and resistance to the varied climates found across Utah, Idaho, Iowa, and Nebraska. It offers excellent protection against the elements, ensuring your workshop remains dry and secure.

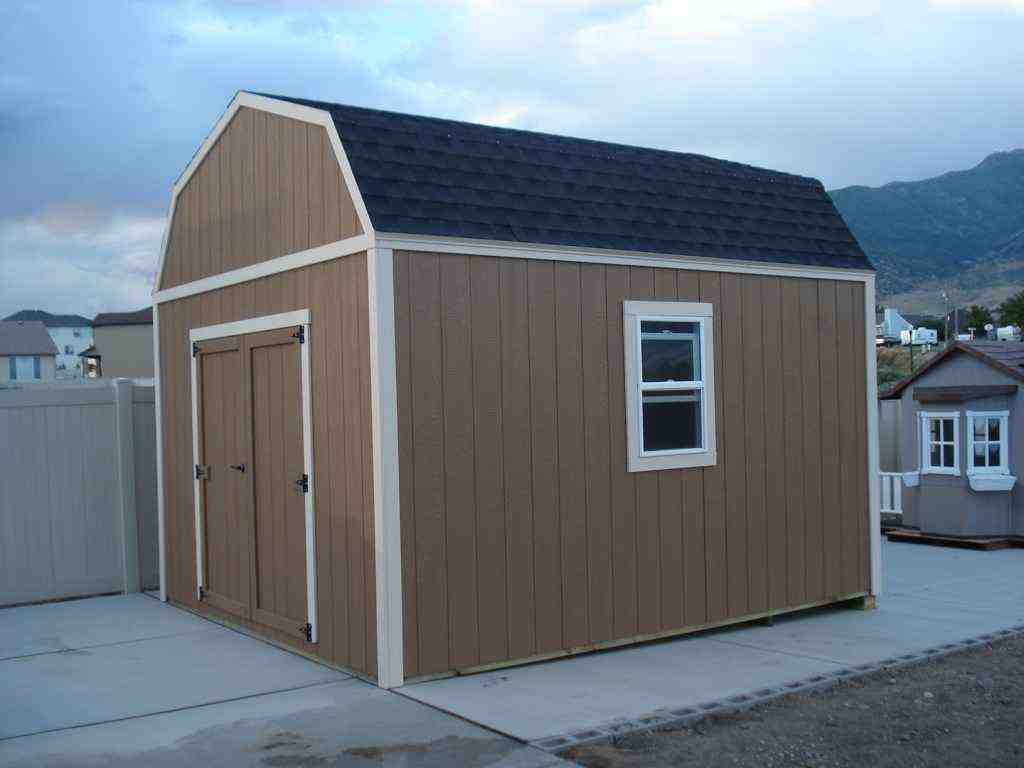

When it comes to roofing, you can choose between classic architectural shingles or a metal roof, both providing reliable protection. Consider the roof style that best suits your needs. A-frame roofs offer a traditional look, while barn-style gambrel roofs maximize headroom and provide additional overhead storage space.

Step 3: Customizing the Interior for Woodworking

The interior layout is where your shed wood workshop truly comes to life. Planning your space around your workflow is critical for efficiency and safety. Position your workbench, table saw, and miter saw strategically to allow for easy movement and material handling.

Consider placing your primary workbench in a central location or against a wall that receives ample natural light. Many woodworkers opt for a sturdy, level workbench designed to their preferred height. This can significantly improve comfort and reduce fatigue during long projects.

To optimize space and keep your floor clear of clutter, accept vertical storage solutions. Wall-mounted systems, such as French cleats or pegboards, are excellent for organizing hand tools, clamps, and other frequently used items. This keeps them within easy reach while freeing up precious workbench space.

For lumber and larger supplies, consider adding shelving units along walls or installing a loft to provide significant storage for raw materials. For larger, heavier tools like a band saw or planer, consider putting them on mobile bases. This allows you to easily move them around as needed, changing your workshop layout for different projects.

Step 4: Power, Lighting, and Ventilation

A functional shed wood workshop demands reliable power, ample lighting, and effective ventilation. Proper electrical planning is paramount for safety and efficiency. For everyone’s safety, we strongly recommend working with a licensed electrician; you can find valuable resources at the Electrical Safety Foundation International (ESFI).

An electrician can ensure your workshop has plenty of outlets, strategically placed near your power tools and workbench. They can also install dedicated 240v circuits for larger machinery. This prevents overloading circuits and reduces fire hazards.

Bright, consistent lighting is crucial for precision woodworking. We recommend installing bright LED overhead lights to illuminate the entire space. Complement this with task lighting at your workbench, such as adjustable lamps, to eliminate shadows and improve visibility.

Maximize natural light by incorporating windows or even skylights into your design. This not only reduces electricity costs but also creates a more pleasant working environment. Good ventilation is equally essential for safety and comfort, so install windows that open and consider a dust collection system to keep the air clean.

Step 5: Year-Round Comfort and Climate Control

To make your shed wood workshop a comfortable and productive space in every season, proper insulation and climate control are key. Insulating the walls, ceiling, and floor will help regulate internal temperatures. For the floor, we often advise on methods that prevent dampness and provide an additional layer of insulation.

Once insulated, a small electric heater can keep the space warm during winter, while a window AC unit can provide relief in the summer. Sealing all gaps around doors and windows with weatherstripping and caulk is vital. This maximizes energy efficiency and prevents drafts, dust, and pests from entering your workshop.

This comprehensive approach ensures your tools and materials are protected from extreme temperature fluctuations and humidity. It prevents wood from warping and metal tools from rusting. A comfortable workshop means more time spent on your craft, regardless of the weather outside.

Step 6: Maintenance and Protecting Your Investment

A shed wood workshop is a significant investment that, with proper care, will serve you well for decades. Establishing a regular maintenance schedule is essential for ensuring its longevity and protecting your tools and projects. Inspect the exterior of your shed annually, paying close attention to the LP SmartSide panel siding and trim.

Regularly clear debris from the roof to prevent water buildup and inspect the roofing material for any signs of wear or damage. Also, check the seals around windows and doors, replacing any worn weatherstripping or recaulking as needed to maintain a weather-tight enclosure.

Applying a quality wood preservative to any exposed timber or freshly cut ends will further improve its resistance to rot and insect damage. By being proactive with these simple maintenance tasks, you’ll ensure your shed wood workshop remains a functional and inspiring space for many years to come.

Frequently Asked Questions about Shed Wood Workshop

How big should my shed wood workshop be?

For most hobbyists, a 12’x16′ shed offers a great starting point, providing ample room for a workbench and several tools. If you plan to house larger machinery like a full-size table saw or jointer, or need space for large projects, consider a more spacious and larger workshop.

Do I need a permit for a shed wood workshop?

Permit requirements vary significantly by location within Utah, Idaho, Iowa, and Nebraska. Generally, sheds over 120 or 200 square feet often require a permit. It’s always best to contact your local city or county building department before you begin any construction to understand specific regulations.

How much does a custom shed wood workshop cost?

The cost of a custom shed wood workshop depends on size, materials, and features like insulation or electrical wiring. Investing in quality construction ensures a durable workspace that adds value to your property.

How do I get electricity in my shed?

We highly recommend hiring a licensed electrician to run power to your shed. They will safely install a dedicated line from your home’s main panel to a subpanel in the workshop. This ensures all wiring meets local codes, is properly grounded, and prevents fire hazards.

What’s the best way to organize tools in a small workshop?

Maximize vertical space with wall-mounted storage like French cleat systems or pegboards for hand tools. This keeps your workbench clear. For larger power tools, use mobile bases with locking casters to keep your floor space flexible and open when they’re not in use.

Your Dream Shed Wood Workshop Awaits

Building your ideal shed wood workshop is a rewarding journey, changing a simple structure into a hub of creativity and productivity. With a solid plan, quality materials custom for durability, and a functional layout designed around your woodworking needs, you’ll create a space that inspires every project.

At Wright’s Shed Co., we turn your vision into reality with custom-built sheds designed specifically for dedicated craftsmen like you, offering robust construction and lasting quality across Utah, Idaho, Iowa, and Nebraska.

Ready to build your dream workshop? Explore our custom-built storage sheds and start designing today!